Key Takeaways

- Establish strong supplier relationships to improve reliability and cost-effectiveness.

- Leverage automation and digital technologies to enhance supply chain visibility and efficiency.

- Implement sustainable practices to meet environmental standards and reduce costs.

- Conduct regular risk assessments to identify and mitigate potential disruptions.

Efficient management of industrial equipment supply chains is critical for businesses aiming to maintain smooth operations, minimize downtime, and reduce operational costs. Best practices in this field focus on optimizing procurement processes, ensuring the timely delivery of essential machinery, and maintaining high-quality control standards. By adopting strategies such as accurate demand forecasting, inventory management, and supplier relationship management, organizations can strengthen the reliability and resilience of their supply chains, even in complex industrial environments.

Working with experienced industrial suppliers in North Carolina can provide valuable insights into sourcing strategies, vendor evaluation, and logistics coordination. Establishing clear communication channels, implementing robust tracking systems, and continuously reviewing supply chain performance are essential steps to mitigate disruptions. These approaches not only improve operational efficiency but also foster long-term partnerships with suppliers, supporting sustainable growth and adaptability in a rapidly evolving industrial landscape.

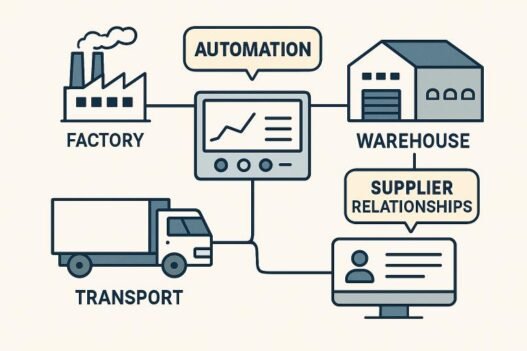

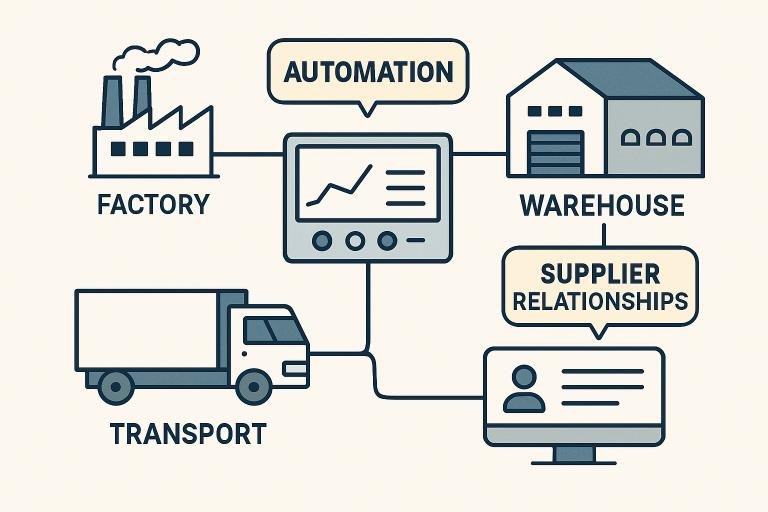

Building Strong Supplier Relationships

Collaborative supplier relationships remain the bedrock of an effective supply chain. Treating suppliers as strategic partners yields cost savings, greater reliability, and innovation. Successful industrial companies routinely engage their suppliers in open, transparent communication, share forecasts, and align on values such as ethical production and sustainability. This cooperation enhances problem-solving and helps ensure the availability of materials during tight market conditions.

Leveraging Automation and Digitalization

The modern supply chain is increasingly driven by automated systems and digital technologies. Using IoT sensors, AI-driven analytics, and digital platforms brings real-time visibility, automates manual processes, and reduces human error throughout the equipment supply chain. Digitalization allows companies to identify and address bottlenecks early, optimize material flows, and respond promptly to unexpected market shifts. These tools support more informed decisions and virtually eliminate blind spots that lead to costly downtime or excess inventory.

Implementing Sustainability Practices

Integrating sustainability into supply chain operations is not only a regulatory imperative but also a pathway to long-term cost reduction and improved brand reputation. Using renewable energy, sourcing eco-friendly materials, and designing durable, repairable products reflect a commitment to environmental stewardship. Industrial organizations that embrace these methods often gain competitive advantages, such as preferred status with sustainability-minded clients or eligibility for green incentives. Sustainable supply chain practices also dovetail with the shift toward circular economy principles, reducing waste and maximizing resource use.

Conducting Regular Risk Assessments

Regular risk assessment is essential to identify and mitigate vulnerabilities within industrial supply chains. By stress-testing systems and evaluating supplier dependencies, businesses can anticipate disruptions, ranging from natural disasters to geopolitical instability. Effective risk management involves developing contingency plans, maintaining safety stock, and diversifying supplier bases to ensure operational continuity. This proactive stance protects against both frequent issues, such as shipment delays, and rare, high-impact risks.

Optimizing Inventory Management

Effective inventory management balances the need for availability with a focus on cost containment. Digital inventory systems and just-in-time (JIT) methodologies give organizations the agility to quickly adjust to market fluctuations while minimizing excess stock and associated carrying costs. End-to-end transparency enables accurate tracking, enabling companies to respond rapidly to supply or demand changes. The outcome is a more efficient, lean supply chain that can scale as needed.

Enhancing Collaborative Planning

Joint planning and shared data platforms with suppliers, logistics partners, and customers lead to dramatically improved outcomes. Enhanced collaboration increases information exchange, shortens response times, and helps all parties align around market demand, production schedules, or regulatory changes. Supply chain partners who embrace frequent, strategic communication stand a much better chance of staying ahead of disruption and sharing in efficiency gains.

Utilizing Data Analytics for Decision-Making

Data-driven supply chains outperform those reliant on intuition or outdated forecasts. AI-powered platforms process vast troves of operational data, enabling predictive analytics, precise demand planning, and rapid identification of emerging challenges or opportunities. Advanced analytics empower leadership teams to make fast, evidence-based decisions that align with business goals, creating a clear competitive edge.

Fostering a Culture of Continuous Improvement

Staying ahead in industrial supply chain management means never settling for the status quo. A culture of continuous improvement encourages employees at all levels to seek out bottlenecks, adopt new technologies, and refine existing processes. Consistent training, technology investments, and benchmarking against industry leaders promote organizational learning while driving operational excellence. Companies committed to constant evolution are best positioned to adapt to industry shifts and capture new market opportunities.

Conclusion

Optimizing industrial equipment supply chains requires a holistic approach that balances reliability, efficiency, and innovation. By cultivating strong supplier relationships, embracing automation and digital tools, integrating sustainability, and continuously assessing risks, organizations can build resilient operations that adapt to market shifts. Leveraging data-driven insights, collaborative planning, and a culture of continuous improvement ensures that supply chains remain agile, cost-effective, and future-ready, supporting long-term business growth in a competitive industrial landscape.