Introduction to 316L Turned, Ground, and Polished (TGP) Stainless Steel

316L stainless steel, renowned for its low carbon content and robust corrosion resistance, is a top choice for manufacturers requiring reliability in aggressive environments. When processed as Turned, Ground, and Polished (TGP), this alloy achieves a highly precise and smooth surface finish, elevating its suitability for critical applications in demanding industries. For more in-depth technical specifications, this website provides a comprehensive product overview.

What differentiates 316L TGP from standard stainless steel is the added assurance of consistent dimensional accuracy combined with a flawless finish. These factors are vital when reliable performance and hygiene are non-negotiable—think pharmaceutical, food processing, or marine settings. Ultimately, the investment in 316L TGP is not just about the immediate performance boost, but also about the long-term reliability that shields users from downstream costs.

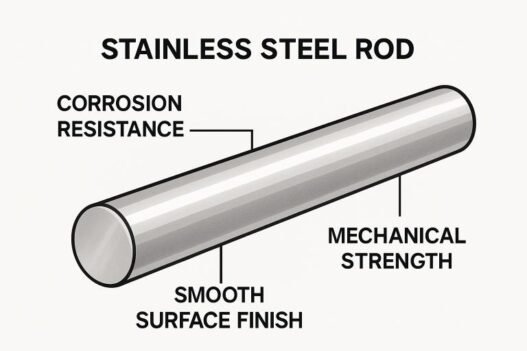

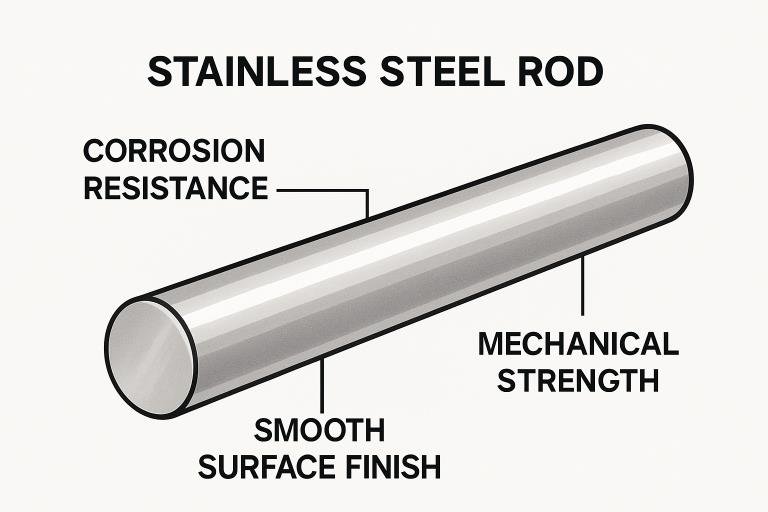

Key Properties and Advantages of 316L TGP

- Corrosion Resistance:Thanks to its low carbon composition, 316L resists sensitization during welding, minimizing the risk of intergranular corrosion. This makes it invaluable for industries confronted by harsh chemicals, saltwater, or acidic substances.

- Mechanical Strength:The alloy maintains outstanding tensile and yield strength, ensuring components can withstand heavy loads and mechanical stresses without deforming or failing.

- Superior Surface Finish:The TGP process delivers a consistent, polished finish that not only looks pristine but also reduces friction and wear. This is especially important for moving parts and applications with high hygiene standards, such as medical devices or food handling equipment.

These properties help explain why the initial price tag for 316L TGP is surpassed by its value over the product lifecycle. Improved performance, minimal maintenance, and durability are essential considerations for engineers calculating the total cost of ownership (TCO).

Comparative Cost Analysis: 316L vs. 304L Stainless Steel

From a procurement standpoint, 316L stainless steel typically commands a price premium over 304L, largely attributable to the inclusion of molybdenum in its composition. This ingredient significantly enhances its corrosion resistance, especially under chloride or acidic exposures that are not well-tolerated by 304L.

For example, a 2-inch sanitary valve made from 304L stainless steel typically ranges from $80 to $150, while the same part fabricated from 316L stainless steel can cost $120 to $220. While the upfront difference is clear, for applications where failure means high replacement costs, contamination risks, or hazardous conditions, the extra investment offers peace of mind.

Balancing immediate procurement budgets with projected maintenance, downtime, and replacement costs is key. In sectors that face demanding environmental conditions, this upfront investment typically results in net savings over the equipment’s usable life, minimizing costly interruptions.

Applications Where 316L TGP Excels

- Medical Devices:316L TGP plays a crucial role in surgical instruments and biomedical implants, where biocompatibility and corrosion resistance have a direct impact on patient safety and device longevity.

- Marine Equipment:Withstanding saltwater corrosion, 316L TGP is ideal for shipbuilding, offshore platforms, and underwater structures.

- Food Processing:The ultra-smooth surface finish ensures that sanitary conditions are achieved and maintained, streamlining cleaning processes and minimizing contamination risks.

From industrial mixers to robotic surgical arms, the versatility of 316L TGP continues to expand as new engineering challenges demand more from its materials. The investment in this alloy translates to regulatory compliance, fewer recalls, and greater brand credibility in the marketplace.

Long-Term Benefits and Return on Investment

The true value of 316L TGP is realized over time through lower maintenance costs, fewer unplanned outages, and a notable extension in service life. In pharmaceutical plants, where equipment must withstand aggressive cleaning regimens, operations switching to 316L TGP have documented lifecycle cost reductions nearing 30%. This is due to fewer part replacements and reduced downtime related to corrosion-induced failures.

Lower maintenance expenses and reliable performance result in reduced operational risk, particularly in high-stakes industries like healthcare and energy. Many organizations have reported significant improvements in asset uptime and process reliability after transitioning to 316L TGP components.

Market Trends and Availability

The growing demand for advanced stainless steels is closely linked to global investment in infrastructure and renewable energy. Governments are investing more than $9 trillion in new bridges, pipelines, public transportation, and solar energy installations by 2030, all of which require robust materials capable of withstanding decades in harsh conditions. As reported by Reuters, this trend is only accelerating, encouraging steady improvements in the availability and pricing of 316L TGP.

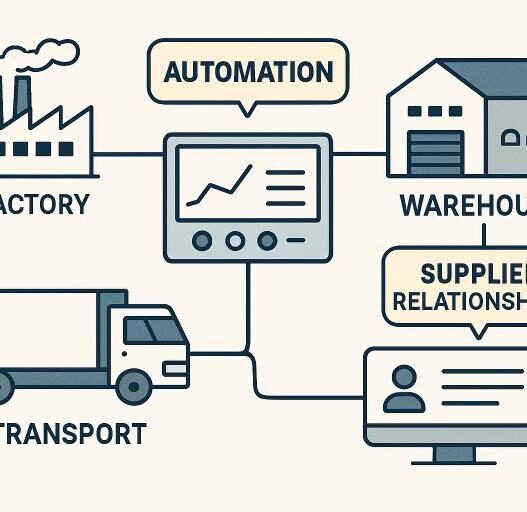

Ultimately, a healthy competitive landscape for manufacturers and suppliers means better access for buyers—both in price points and turnaround times. Reliable supply chains also lend further confidence to investing in this premium-grade alloy now and into the future.

Considerations Before Investing

- Application Requirements:Determine whether the superior attributes of 316L TGP are essential for your specific use case. Over-specifying for benign conditions may be unnecessary, while underestimating needs in demanding environments can have severe consequences.

- Budget Constraints:Consider if your available resources can absorb the upfront premium—and whether the projected lifecycle savings align with your financial objectives.

- Supplier Reliability:Ensure that your chosen supplier can consistently meet quality standards and delivery schedules. Long-term partnerships stabilize supply chains and safeguard against market volatility.

Final Thoughts

Although it comes at a higher initial cost compared to common materials like 304L stainless steel, 316L TGP’s enhanced durability, superior corrosion resistance, and exceptional surface properties deliver enduring value in the form of lower long-term costs and increased reliability. For industries with strict performance and safety mandates, investing in 316L TGP isn’t just justified—it’s often essential. Evaluating your specific needs, supply options, and total cost of ownership will confirm whether this advanced material aligns with your operational strategy.